Introduction

Electromagnetic Compatibility (EMC) testing is an essential aspect of product development. Ensuring that your product functions properly in its intended environment—without causing or falling victim to electromagnetic interference—is critical for success. Beyond compliance, EMC testing bolsters reliability enhances customer trust, and enables smoother market entry.

What is EMC Testing?

Definition

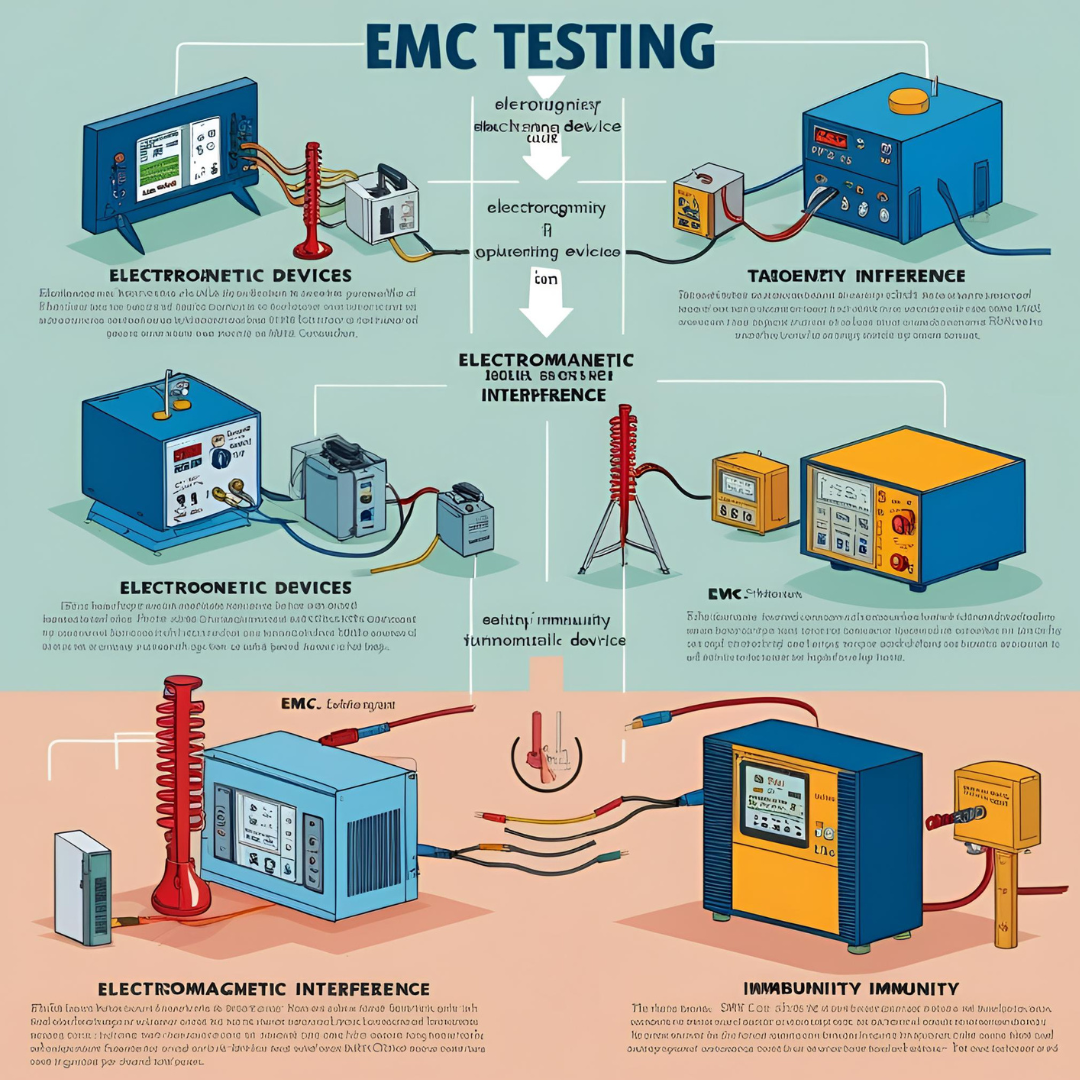

EMC testing assesses a product’s ability to operate as intended in its environment without being affected by or emitting excessive electromagnetic interference (EMI).

Types of EMC Tests

- Emissions Testing: Measures the electromagnetic interference a product emits.

- Immunity Testing: Ensures a product can function despite external EMI.

- Electrostatic Discharge (ESD) Testing: Evaluates resistance to static electricity discharges.

- Radiated and Conducted Emissions Testing: Checks for interference caused by radiation and physical connections.

Why EMC Testing is Important

Product Safety

EMC testing ensures products do not pose risks due to interference with medical devices, aviation systems, or other critical technologies.

Regulatory Compliance

Governments and regulatory bodies require compliance with EMC standards to ensure public safety and compatibility across products.

Market Acceptance

A product’s ability to meet EMC standards builds trust and confidence among consumers and industry stakeholders, fostering broader market access.

Key Benefits of EMC Testing

Ensures Compliance with Regulations

Governments and industry bodies enforce strict EMC regulations. Meeting these standards is essential to bring your product to market without legal complications.

Enhances Product Safety

EMC testing identifies potential interference issues that may cause electronic malfunctions, preventing hazards and ensuring safe consumer operation.

Improves Performance and Reliability

By mitigating interference risks, EMC testing boosts product performance and operational stability, leading to a more reliable user experience.

Protects Brand Reputation

Products that fail due to interference issues can damage a company’s reputation. Ensuring EMC compliance helps maintain customer trust and brand loyalty.

The Consequences of Skipping EMC Testing

Market Delays

Non-compliant products often face recalls or launch delays, leading to lost revenue and customer dissatisfaction.

Increased Costs

Addressing EMC issues post-launch is far more expensive than resolving them during development.

Legal and Financial Risks

Failure to comply with EMC regulations may result in penalties and potential lawsuits.

How EMC Testing Works

Testing for Emissions

This step evaluates the electromagnetic emissions from your product to ensure they don’t interfere with other devices.

Susceptibility Testing

This phase tests how your product responds to external electromagnetic interference.

Common Testing Environments

- Radiated Emissions Chambers: Simulate real-world conditions for accurate assessments.

- Conducted Emissions Testing Labs: Analyzed interference through power lines and cables.

When to Conduct EMC Testing

Early testing during the design phase helps identify and correct issues before production. Regular testing throughout development ensures ongoing compliance.

Choosing the Right EMC Testing Partner

Selecting a certified and experienced testing lab ensures accurate results and comprehensive compliance support.

EMC testing is a non-negotiable step for product success. Ensure your product meets compliance, delivers exceptional performance, and gains customer trust through rigorous testing practices.