In today’s complex and litigious world, product liability is a significant concern for manufacturers, distributors, and retailers. A single defective product can lead to severe injuries, property damage, and costly lawsuits. While insurance offers a degree of protection, the best strategy for minimizing product liability risks lies in prevention. And at the heart of prevention lies comprehensive compliance testing.

This blog post will delve into the critical role that compliance testing plays in mitigating product liability risks. We’ll explore what compliance testing is, why it’s essential, the types of tests conducted, the benefits beyond risk reduction, and how to implement an effective compliance testing program.

What is Compliance Testing?

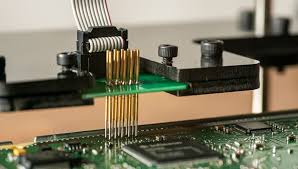

Compliance testing is the process of evaluating a product, service, or system against a defined set of standards, regulations, and specifications. These standards are typically established by governmental bodies, industry organizations, or internal company policies. The goal is to ensure that the product meets the minimum requirements for safety, performance, quality, and environmental impact.

It’s more than just a superficial check. Compliance testing often involves a rigorous and methodical approach, incorporating:

Design Review: Analyzing the product’s design for potential flaws and hazards.

Material Testing: Assessing the properties and safety of the materials used in the product.

Performance Testing: Evaluating the product’s functionality under various operating conditions.

Safety Testing: Identifying and mitigating potential safety hazards, such as electrical shocks, fire risks, or mechanical failures.

Environmental Testing: Determining the product’s impact on the environment and ensuring compliance with environmental regulations.

Documentation Review: Verifying that the product’s documentation, including manuals and labels, accurately reflects its features and safety precautions.

Compliance testing can be conducted in-house by a company’s own quality assurance department or outsourced to independent testing laboratories. The choice depends on factors such as the complexity of the product, the availability of resources, and the need for independent verification.

Why is Compliance Testing Essential for Reducing Product Liability?

Product liability lawsuits often arise from allegations of negligence, strict liability, or breach of warranty. Compliance testing helps to address these potential legal claims by providing evidence that the product was designed, manufactured, and marketed with reasonable care. Here’s a breakdown of why compliance testing is crucial:

Demonstrating Due Diligence: By conducting thorough compliance testing, companies can demonstrate that they took reasonable steps to ensure the safety and quality of their products. This can be a powerful defense against allegations of negligence. The testing records serve as documented proof of this diligence.

Identifying and Correcting Design Flaws: Compliance testing can uncover hidden design flaws or manufacturing defects that could lead to product failures or injuries. Early detection and correction of these problems can prevent costly recalls and lawsuits. Imagine, for instance, a bicycle manufacturer discovering through fatigue testing that the handlebars are prone to cracking under stress. This discovery allows them to redesign the handlebars before the product reaches consumers, preventing potential accidents and liability.

Ensuring Adherence to Safety Standards: Many industries have specific safety standards that products must meet. Compliance testing ensures that products adhere to these standards, reducing the risk of injuries and property damage. Examples include UL standards for electrical products, ASTM standards for toys, and ISO standards for medical devices.

Meeting Regulatory Requirements: Governments often impose mandatory compliance testing requirements for certain products. Failure to comply with these regulations can result in fines, penalties, and even product recalls. Compliance testing ensures that products meet all applicable regulatory requirements.

Mitigating Strict Liability: In many jurisdictions, manufacturers can be held strictly liable for injuries caused by defective products, regardless of negligence. However, a robust compliance testing program can help to demonstrate that the product was not defective at the time it left the manufacturer’s control. This can be a crucial factor in mitigating strict liability claims.

Improving Product Quality and Performance: Compliance testing not only identifies safety hazards but also helps to improve the overall quality and performance of products. By identifying areas for improvement, companies can enhance customer satisfaction and reduce the risk of product returns.

Enhancing Brand Reputation: Products that have undergone rigorous compliance testing are more likely to be seen as safe and reliable. This can enhance brand reputation and increase customer loyalty. Consumers are increasingly aware of product safety and are more likely to purchase products from companies that prioritize compliance.

Types of Compliance Tests:

The specific types of compliance tests conducted will vary depending on the nature of the product and the applicable regulations. However, some common types of tests include:

Electrical Safety Testing: This type of testing ensures that electrical products are safe to use and do not pose a risk of electrical shock or fire. It includes tests such as insulation resistance testing, ground continuity testing, and leakage current testing.

Mechanical Safety Testing: This type of testing evaluates the mechanical properties of a product to ensure that it is strong enough to withstand normal use and does not pose a risk of mechanical failure. It includes tests such as tensile testing, compression testing, and impact testing.

Chemical Safety Testing: This type of testing identifies and quantifies the presence of hazardous chemicals in a product. It ensures that the product complies with regulations such as REACH and RoHS.

Environmental Testing: This type of testing evaluates the product’s impact on the environment. It includes tests such as emissions testing, waste disposal testing, and energy efficiency testing.

Performance Testing: This type of testing evaluates the product’s performance under various operating conditions. It includes tests such as durability testing, reliability testing, and functionality testing.

Electromagnetic Compatibility (EMC) Testing: This type of testing ensures that the product does not interfere with the operation of other electronic devices and is not susceptible to interference from other devices.

Materials Testing: This evaluates the composition, strength, and durability of the materials used in the product to ensure they meet safety and performance requirements.

Benefits Beyond Risk Reduction:

While the primary benefit of compliance testing is reducing product liability risks, it also offers a number of other advantages:

Improved Product Design: The testing process can provide valuable feedback on product design, leading to improvements in safety, performance, and usability.

Reduced Manufacturing Costs: By identifying and correcting defects early in the manufacturing process, compliance testing can help to reduce scrap rates and rework costs.

Increased Customer Satisfaction: Safe and reliable products lead to increased customer satisfaction and loyalty.

Enhanced Market Access: Compliance with international standards can facilitate market access to countries with strict regulatory requirements.

Competitive Advantage: Companies that prioritize compliance testing are often seen as more trustworthy and reliable, giving them a competitive advantage in the marketplace.

Implementing an Effective Compliance Testing Program:

Implementing an effective compliance testing program requires careful planning and execution. Here are some key steps to consider:

- Identify Applicable Standards and Regulations: The first step is to identify all applicable standards and regulations for the product in question. This may involve consulting with industry experts, regulatory agencies, and standards organizations.

- Develop a Testing Plan: A comprehensive testing plan should be developed that outlines the specific tests to be conducted, the testing procedures to be followed, and the acceptance criteria to be used.

- Select a Testing Laboratory: Companies can choose to conduct testing in-house or outsource it to an independent testing laboratory. If outsourcing, it’s crucial to select a reputable laboratory with the necessary expertise and equipment. Ensure the lab is accredited and recognized by relevant authorities.

- Conduct the Tests: The tests should be conducted according to the testing plan and documented thoroughly. Any deviations from the plan should be noted and justified.

- Analyze the Results: The test results should be analyzed to determine whether the product meets the acceptance criteria. If any failures are identified, corrective actions should be taken to address the underlying causes.

- Document the Results: All test results should be documented thoroughly and retained for future reference. This documentation may be required for regulatory compliance and can also be used as evidence in product liability lawsuits.

- Regularly Review and Update the Program: The compliance testing program should be reviewed and updated regularly to ensure that it remains effective and reflects the latest standards and regulations.

Conclusion:

Compliance testing is an indispensable tool for reducing product liability risks. It’s an investment that pays dividends in the form of safer products, reduced costs, enhanced brand reputation, and improved market access. By implementing a comprehensive compliance testing program, companies can demonstrate their commitment to product safety and protect themselves from costly legal claims. In a world where product safety is paramount, compliance testing is no longer optional—it’s a necessity. It’s an integral part of responsible manufacturing and a cornerstone of building trust with consumers.