In today’s interconnected world, electronic devices are ubiquitous. From smartphones and laptops to industrial machinery and medical equipment, our lives depend on their reliable operation. However, the electromagnetic environment is increasingly crowded, making it crucial to ensure that electronic products function as intended without interfering with other devices or being susceptible to interference themselves. This is where Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) testing come into play.

This comprehensive guide will delve deep into the world of EMI/EMC testing, covering everything from the fundamental concepts to the practical application of testing procedures. Whether you’re an engineer, a product developer, or simply curious about how electronic devices are regulated, this guide will provide you with a solid understanding of this vital aspect of product development.

Understanding EMI and EMC: Laying the Foundation

Before diving into the specifics of testing, it’s essential to grasp the core concepts of EMI and EMC.

Electromagnetic Interference (EMI): EMI refers to the disturbances caused by electromagnetic energy that can negatively impact the performance of electronic devices or systems. It can manifest as noise, signal degradation, data corruption, or even complete malfunction. EMI can be intentional (e.g., radio transmissions) or unintentional (e.g., switching power supplies).

Electromagnetic Compatibility (EMC): EMC refers to the ability of a device or system to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbances to other equipment in that environment. Essentially, it means a product is both immune to interference and doesn’t generate excessive interference itself.

Two Key Aspects of EMC:

Emissions: This refers to the electromagnetic energy radiated or conducted by a product. Emissions testing ensures that a product doesn’t exceed the specified limits for electromagnetic noise.

Immunity (Susceptibility): This refers to a product’s ability to withstand electromagnetic disturbances without experiencing performance degradation. Immunity testing ensures a product can operate reliably in the presence of electromagnetic noise.

Sources and Types of EMI:

Understanding the different sources and types of EMI is crucial for designing and testing products effectively.

Conducted EMI: Interference transmitted through wires, cables, or printed circuit board traces. Common sources include switching power supplies, digital circuits, and motors.

Radiated EMI: Interference emitted through the air in the form of electromagnetic waves. Sources include high-frequency oscillators, antennas, and leaky enclosures.

Common EMI Sources:

Switching Power Supplies: Produce significant high-frequency noise due to rapid switching of current.

Microprocessors and Digital Circuits: Clock signals and data transitions generate harmonic frequencies.

Motors and Relays: Inductive switching can create voltage spikes and radio frequency interference (RFI).

Radio Transmitters and Receivers: Intentionally designed to emit and receive electromagnetic radiation.

Lighting Systems: Fluorescent lights and LEDs can generate EMI.

The Importance of EMI/EMC Testing: Why Bother?

EMI/EMC testing is not merely a compliance exercise; it’s a critical step in ensuring product quality, reliability, and safety. Here’s why it’s so important:

Regulatory Compliance: Most countries have regulations that mandate EMI/EMC compliance for electronic products before they can be sold or used. These regulations are enforced to protect the public from potential health hazards and prevent interference with essential services like radio communications and emergency services. Examples include FCC regulations in the United States, CE marking in Europe, and VCCI in Japan.

Product Reliability and Performance: EMI/EMC testing helps identify potential weaknesses in a product’s design that could lead to performance degradation, malfunction, or even premature failure. By addressing these issues early in the development process, manufacturers can improve product reliability and reduce warranty costs.

Coexistence with Other Devices: In today’s densely populated electromagnetic environment, ensuring that a product doesn’t interfere with other devices is crucial. EMI/EMC testing helps prevent interference with critical equipment in industries such as healthcare, aviation, and telecommunications.

Safety: In some cases, excessive EMI can pose a safety hazard. For example, strong electromagnetic fields can interfere with the operation of pacemakers or other implanted medical devices. EMI/EMC testing helps ensure that products meet safety standards and don’t pose a risk to human health.

Cost Savings: Identifying and addressing EMI/EMC issues early in the development cycle is significantly cheaper than fixing them later, especially after the product is in mass production. Early testing can prevent costly redesigns, delays in market launch, and potential product recalls.

Competitive Advantage: A product that has been thoroughly tested and meets EMI/EMC standards demonstrates a commitment to quality and reliability. This can be a significant competitive advantage, especially in markets where customers are particularly sensitive to performance and safety.

Key EMI/EMC Standards and Regulations:

Navigating the complex landscape of EMI/EMC standards and regulations can be challenging. Here’s an overview of some of the most important ones:

FCC (Federal Communications Commission) – United States: Regulates radio frequency devices and sets limits for emissions in the United States. Part 15 is the most relevant section for many electronic devices, covering unintentional radiators.

CE Marking – European Union: A mandatory conformity marking for products sold in the European Economic Area (EEA). It signifies that a product meets the essential requirements of relevant European directives, including the EMC Directive (2014/30/EU).

CISPR (Comité International Spécial des Perturbations Radioélectriques): An international organization that develops EMC standards used globally. These standards are often referenced in national regulations.

EN (European Norms): European standards developed by organizations like CENELEC (European Committee for Electrotechnical Standardization). These standards are often harmonized with CISPR standards.

IEC (International Electrotechnical Commission): Develops international standards for electrical and electronic technologies, including those related to EMC.

MIL-STD (Military Standards): Used by the US Department of Defense for military equipment. These standards often have stricter requirements than commercial standards.

VCCI (Voluntary Control Council for Interference by Information Technology Equipment) – Japan: A voluntary organization that sets EMC standards for IT equipment in Japan.

Commonly Referenced Standards:

CISPR 22/EN 55022: Information Technology Equipment – Radio disturbance characteristics – Limits and methods of measurement.

CISPR 32/EN 55032: Electromagnetic compatibility of multimedia equipment – Emission requirements.

CISPR 24/EN 55024: Information technology equipment – Immunity characteristics – Limits and methods of measurement.

CISPR 35/EN 55035: Electromagnetic compatibility of multimedia equipment – Immunity requirements.

IEC 61000-4-x series: A series of standards covering different immunity tests, such as electrostatic discharge (ESD), radiated susceptibility, and conducted susceptibility.

Choosing the Right Standard:

Selecting the appropriate EMI/EMC standard depends on several factors, including:

Type of product: Different standards apply to different product categories (e.g., IT equipment, medical devices, automotive electronics).

Target market: The regulatory requirements vary from country to country.

Intended use: Products intended for use in harsh environments may require more stringent testing.

It’s crucial to consult with EMC experts and review the relevant regulations to determine the appropriate standards for your product.

EMI/EMC Testing Methods and Procedures:

EMI/EMC testing involves a variety of methods and procedures designed to evaluate a product’s emissions and immunity characteristics. Here’s an overview of some common tests:

Emissions Testing:

Conducted Emissions: Measures the electromagnetic noise conducted on power lines, signal cables, and other conductive paths. A Line Impedance Stabilization Network (LISN) is typically used to provide a defined impedance to the power line during testing.

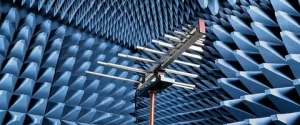

Radiated Emissions: Measures the electromagnetic energy radiated from the product’s enclosure, cables, and other surfaces. Tests are typically performed in an anechoic chamber or Open Area Test Site (OATS) using antennas to detect the radiated emissions.

Immunity (Susceptibility) Testing:

Electrostatic Discharge (ESD): Simulates the effects of static electricity discharge on a product. A charged capacitor is discharged onto the product through a defined air gap or contact discharge.

Radiated Susceptibility: Exposes the product to electromagnetic fields of varying frequencies and amplitudes to assess its immunity to radiated interference. This is typically performed in an anechoic chamber using antennas to generate the electromagnetic fields.

Conducted Susceptibility: Injects electromagnetic noise onto the power lines, signal cables, and other conductive paths to assess the product’s immunity to conducted interference.

Electrical Fast Transient/Burst (EFT/Burst): Simulates the effects of transient disturbances caused by switching inductive loads or other fast switching events. A series of short, high-voltage pulses are injected onto the power lines.

Surge Immunity: Simulates the effects of voltage surges caused by lightning strikes or power grid disturbances. High-energy pulses are applied to the power lines.

Voltage Dips and Interruptions: Simulates the effects of voltage sags and power outages on the product. The voltage supply is reduced or interrupted for a specified duration.

Magnetic Field Immunity: Exposes the product to magnetic fields to assess its immunity to magnetic interference. This is particularly relevant for products that contain magnetic sensors or are used near magnetic field sources.

Testing Equipment:

EMI/EMC testing requires specialized equipment, including:

Spectrum Analyzers: Used to measure the frequency and amplitude of electromagnetic signals.

EMI Receivers: Specialized receivers designed to meet the requirements of EMC standards. They have specific bandwidths, detectors, and filters for accurate measurements.

Antennas: Used to radiate and receive electromagnetic energy during radiated emissions and susceptibility testing.

LISNs (Line Impedance Stabilization Networks): Provide a defined impedance to the power line during conducted emissions testing.

ESD Simulators: Generate electrostatic discharges for ESD immunity testing.

Signal Generators: Used to generate test signals for susceptibility testing.

Amplifiers: Amplify the test signals for radiated and conducted susceptibility testing.

Transient Generators: Generate electrical fast transient/bursts and surge waveforms.

Anechoic Chambers: Shielded rooms lined with absorbing materials to minimize reflections during radiated emissions and susceptibility testing.

Open Area Test Sites (OATS): Open areas with a reflective ground plane used for radiated emissions testing.

The EMI/EMC Testing Process: A Step-by-Step Guide

The EMI/EMC testing process typically involves the following steps:

- Pre-Compliance Testing (Optional): Performing preliminary tests early in the development process to identify potential EMI/EMC issues and address them before formal compliance testing. This can save time and money by preventing costly redesigns later on. This often involves using less formal setups and equipment, focusing on identifying problem areas rather than achieving absolute compliance.

- Test Plan Development: Creating a detailed test plan that outlines the specific tests to be performed, the standards to be followed, the test equipment to be used, and the acceptance criteria.

- Sample Preparation: Preparing the product for testing by configuring it in its intended operating mode and connecting any necessary cables or accessories.

- Test Setup: Setting up the test equipment and the product in accordance with the test plan and the relevant standards.

- Testing Execution: Performing the tests according to the test plan, carefully monitoring the results, and recording any anomalies.

- Data Analysis: Analyzing the test data to determine whether the product meets the acceptance criteria.

- Report Generation: Preparing a comprehensive test report that documents the test setup, procedures, results, and conclusions.

- Corrective Actions (If Necessary): If the product fails to meet the acceptance criteria, identifying the root cause of the failure and implementing corrective actions, such as shielding, filtering, or circuit redesign.

- Re-Testing: Performing re-testing after implementing corrective actions to ensure that the product now meets the requirements.

Best Practices for EMI/EMC Design and Mitigation:

Preventing EMI/EMC problems is always more cost-effective than fixing them after the fact. Here are some best practices for EMI/EMC design and mitigation:

Grounding: Proper grounding is essential for minimizing EMI. Use a solid ground plane and connect all metal parts of the product to the ground plane.

Shielding: Use shielding to enclose noisy circuits or components. Shielding can be implemented using metal enclosures, conductive gaskets, or metalized fabrics.

Filtering: Use filters to suppress unwanted noise on power lines, signal cables, and other conductive paths. Common filter types include common-mode chokes, differential-mode chokes, and feedthrough capacitors.

Component Selection: Choose components with low EMI characteristics, such as low-noise amplifiers and switching power supplies with integrated EMI filters.

PCB Layout: Pay attention to PCB layout to minimize EMI. Keep signal traces short and direct, use a ground plane, and separate noisy circuits from sensitive circuits.

Cable Management: Use shielded cables and minimize cable lengths to reduce radiated emissions and susceptibility. Route cables away from noisy circuits.

Proper Termination: Terminate transmission lines properly to prevent reflections, which can contribute to EMI.

Frequency Selection: Choose operating frequencies that are less likely to cause interference.

Software Mitigation: In some cases, software can be used to mitigate EMI. For example, spread-spectrum clocking can reduce the peak emissions from digital circuits.

Choosing an EMI/EMC Testing Lab:

If you don’t have the in-house capabilities to perform EMI/EMC testing, you’ll need to outsource it to a qualified testing lab. Here are some factors to consider when choosing a lab:

Accreditation: Make sure the lab is accredited by a recognized accreditation body, such as A2LA or NVLAP. Accreditation ensures that the lab meets the required standards for competence and impartiality.

Scope of Accreditation: Verify that the lab’s accreditation covers the specific tests and standards that you need for your product.

Experience: Choose a lab with experience testing products similar to yours.

Equipment: Ensure the lab has the necessary equipment to perform the required tests.

Turnaround Time: Inquire about the lab’s turnaround time for testing.

Cost: Compare the costs of different labs, but don’t choose solely on price. Consider the lab’s experience, accreditation, and turnaround time as well.

Location: A lab that is geographically convenient can save you time and transportation costs.

Communication: Choose a lab that is responsive and provides clear communication throughout the testing process.

The Future of EMI/EMC Testing:

The field of EMI/EMC testing is constantly evolving to keep pace with the ever-increasing complexity of electronic devices and the growing density of the electromagnetic environment. Some trends shaping the future of EMI/EMC testing include:

Higher Frequencies: As devices operate at higher frequencies, the challenges of EMI/EMC testing become more complex. New testing methods and equipment are needed to address these challenges.

Wireless Technologies: The proliferation of wireless technologies is increasing the risk of interference. EMI/EMC testing is becoming increasingly important for wireless devices to ensure they don’t interfere with other wireless systems.

Internet of Things (IoT): The IoT is creating a massive network of interconnected devices. Ensuring the EMC of IoT devices is crucial to prevent interference and ensure reliable operation.

Automated Testing: Automated testing is becoming more common to improve efficiency and reduce testing costs.

Modeling and Simulation: Modeling and simulation tools are increasingly being used to predict EMI/EMC performance and identify potential problems early in the design process.

Smart Grids and Power Electronics: As smart grids and advanced power electronics become more prevalent, ensuring their EMC and resilience against electromagnetic disturbances is paramount for grid stability and reliability.

Conclusion:

EMI/EMC testing is a critical aspect of product development that ensures product quality, reliability, safety, and regulatory compliance. By understanding the fundamentals of EMI and EMC, following best practices for design and mitigation, and working with qualified testing labs, manufacturers can successfully navigate the complex electromagnetic environment and bring reliable and compliant products to market. As technology continues to advance, staying informed about the latest trends and developments in EMI/EMC testing will be essential for maintaining a competitive edge. This guide provides a solid foundation, but continuous learning and adaptation are key to success in this ever-evolving field.