Navigating the Certification Maze: A Comprehensive Guide to Product Safety & Environmental Testing for Arizona Businesses

As an Arizona business owner, you’re likely focused on delivering high-quality products and services that meet your customers’ needs. However, ensuring your products are safe, environmentally sound, and compliant with regulations is paramount, not just for your reputation, but also for the long-term success of your business. That’s where product safety and environmental testing come in.

At H.B. Compliance Solutions, an Arizona-based company specializing in compliance testing, we understand that navigating the complexities of certification can be daunting. This guide aims to demystify the process, outlining the key steps to achieving full certification and ensuring your products meet the rigorous standards required for market access.

Why is Product Safety & Environmental Testing Crucial?

Before we dive into the steps, let’s explore why product safety and environmental testing are so vital for Arizona businesses:

- Consumer Safety: This is the most critical aspect. Rigorous testing ensures your products are safe for their intended use, minimizing the risk of injury, harm, or even fatalities. By prioritizing safety, you build trust with your customers and safeguard your brand reputation.

- Legal Compliance: Federal, state, and local regulations dictate specific safety and environmental standards for various product categories. Failure to comply can result in hefty fines, product recalls, legal liabilities, and even business closure.

- Market Access: Many retailers and distributors require certification before they’ll stock or sell your products. Certification serves as proof that your products meet the required standards and provides a competitive advantage.

- Environmental Responsibility: Demonstrating a commitment to environmental protection is increasingly important to consumers and regulatory bodies. Environmental testing can identify potential impacts and help you implement sustainable practices.

- Enhanced Brand Reputation: Certification signals to customers that your company is committed to quality, safety, and environmental responsibility, building brand loyalty and driving sales.

- Risk Mitigation: Proactive testing helps identify potential product flaws or environmental hazards early in the development process, allowing you to make necessary adjustments before launching to market. This can save significant time, resources, and potential legal costs.

Key Steps to Achieving Full Certification:

The certification process can vary depending on the product type, target market, and applicable regulations. However, the following steps provide a general framework:

1. Identify Applicable Standards and Regulations:

This is arguably the most crucial step. You need to identify which standards and regulations apply to your specific product. This involves understanding:

- Product Type: What type of product are you manufacturing or selling? Different categories have different requirements. For example, electronic devices will need to meet different standards than children’s toys.

- Target Market: Where will your product be sold? Regulations vary between countries and even between states within the US. If you plan to sell nationally or internationally, you need to understand the regulations in each target market.

- Industry-Specific Standards: Are there any industry-specific standards that apply to your product? For example, medical devices have strict regulatory requirements from the FDA.

- Material Composition: What materials are used in your product? Certain materials may be restricted or require specific testing.

Resources for identifying applicable standards include:

- Government Regulatory Agencies: The Consumer Product Safety Commission (CPSC), Environmental Protection Agency (EPA), Food and Drug Administration (FDA), and other agencies provide information on product safety and environmental regulations.

- Industry Associations: Industry-specific associations often publish guidelines and resources related to product safety and compliance.

- Certification Bodies: Organizations like UL, Intertek, and CSA offer testing and certification services and can help you identify applicable standards.

- H.B. Compliance Solutions: As an Arizona-based compliance expert, we can provide a comprehensive regulatory review to identify all applicable standards for your product.

2. Develop a Testing Plan:

Once you’ve identified the relevant standards, you need to develop a comprehensive testing plan. This plan should outline:

- Testing Scope: What specific aspects of the product will be tested?

- Testing Methods: Which testing methods will be used to evaluate the product’s compliance?

- Sample Selection: How many samples will be tested? How will the samples be selected to ensure they are representative of the overall production run?

- Testing Schedule: When will the testing be conducted?

- Budget: How much will the testing cost?

3. Conduct Product Safety & Environmental Testing:

This involves submitting your product samples to a qualified testing laboratory, like H.B. Compliance Solutions. The lab will conduct the tests outlined in your testing plan, using specialized equipment and trained personnel. Common types of testing include:

- Safety Testing: Evaluating the product’s electrical safety, mechanical safety, flammability, and other safety hazards.

- Environmental Testing: Assessing the product’s environmental impact, including emissions, waste generation, and recyclability. This can include testing for RoHS compliance (Restriction of Hazardous Substances) or REACH compliance (Registration, Evaluation, Authorisation and Restriction of Chemicals).

- Performance Testing: Evaluating the product’s performance characteristics, such as durability, reliability, and efficiency.

- Material Testing: Analyzing the composition of materials used in the product to ensure they meet regulatory requirements.

4. Analyze Test Results and Implement Corrective Actions:

After the testing is complete, the lab will provide you with a detailed report outlining the test results. Carefully review the report and identify any areas where the product failed to meet the required standards.

If the product fails any tests, you’ll need to implement corrective actions to address the identified issues. This may involve redesigning the product, changing materials, or modifying manufacturing processes.

5. Re-Test and Verify Compliance:

After implementing corrective actions, you’ll need to re-test the product to verify that it now meets the required standards. This may involve repeating the original tests or conducting additional tests to address the specific issues identified in the initial testing.

6. Obtain Certification:

Once the product has passed all required tests, you can apply for certification from a recognized certification body. The certification body will review the test reports and other documentation to ensure that the product meets all applicable standards.

If the certification body is satisfied that the product is compliant, they will issue a certificate of compliance, which you can use to demonstrate to customers and regulatory agencies that your product meets the required standards, including Canada – Equipment Certification.

7. Maintain Compliance:

Certification is not a one-time event. You need to maintain compliance over the product’s lifecycle. This involves:

- Regular Monitoring: Continuously monitor your product and manufacturing processes to ensure they continue to meet the required standards.

- Periodic Testing: Conduct periodic testing to verify that your product remains compliant.

- Document Control: Maintain accurate records of all testing, inspections, and corrective actions.

- Staying Updated on Regulations: Keep abreast of changes in regulations and standards and adapt your processes accordingly.

Choosing the Right Testing Partner: H.B. Compliance Solutions for Arizona Businesses

Selecting the right testing partner is crucial for a smooth and successful certification process. Here’s why H.B. Compliance Solutions is the ideal choice for Arizona businesses:

- Local Expertise: We are an Arizona-based company with a deep understanding of the regulatory landscape in the state and beyond.

- Comprehensive Testing Services: We offer a wide range of product safety and environmental testing services to meet the needs of various industries.

- Experienced Team: Our team of experienced engineers and technicians are experts in their respective fields and are committed to providing accurate and reliable testing services.

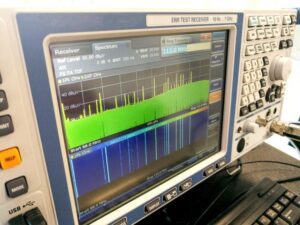

- State-of-the-Art Equipment: We utilize state-of-the-art testing equipment to ensure accurate and reliable results.

- Fast Turnaround Times: We understand the importance of getting your products to market quickly, so we offer fast turnaround times on testing services.

- Personalized Service: We provide personalized service to each of our clients, working closely with you to understand your specific needs and requirements.

- Competitive Pricing: We offer competitive pricing on our testing services, making compliance accessible to businesses of all sizes.

Conclusion:

Achieving full product safety and environmental certification is a complex process, but it’s essential for the long-term success of your Arizona business. By following these key steps and partnering with a reputable testing laboratory like H.B. Compliance Solutions, you can ensure your products meet the required standards, protect your customers, and build a strong brand reputation.

Ready to get started? Contact H.B. Compliance Solutions today for a free consultation. We can help you navigate the certification maze and ensure your products meet the highest standards of safety and environmental responsibility.