EMI Testing Basics

Electromagnetic Interference (EMI) testing is a crucial process for ensuring the reliability and safety of electronic devices. As more and more electronic products are developed and brought to market, the need for this becomes increasingly important. In this article, we will explore the basics of EMI testing, its importance, how it is performed, and the best place for you to conduct this type of testing.

What is EMI Testing basics?

EMI testing is a process of evaluating the level of electromagnetic interference that electronic devices generate or are susceptible to. Electromagnetic interference can be defined as any unwanted electromagnetic energy that can disrupt the proper functioning of other electronic devices. It is essential to identify and measure the level of EMI generated by a device to ensure that it does not cause interference with other electronic devices in its environment.

Ensuring Equipment Certification products meet necessary standards for quality and compliance.

Importance of EMI Testing

This type of testing plays a crucial role in ensuring the reliability and safety of electronic devices. EMI can cause errors, malfunctions, and failures in electronic devices, which can lead to serious consequences, such as loss of data, property damage, or even injury. In some cases, EMI can also interfere with critical systems such as medical equipment or aviation systems, causing potentially life-threatening situations. Adhering to Ecfr.government regulations and standards.

EMI testing basics is a critical step in the product development process, as it helps identify and eliminate EMI issues before the product is released into the market. This ensures that the product is safe, reliable, and compliant with regulatory requirements.

How is EMI Testing Performed?

It involves measuring the level of electromagnetic emissions generated by a device and its susceptibility to electromagnetic interference from other devices. The process typically involves two types of testing: radiated emissions testing and conducted emissions testing. Complying Fcc.government with Federal Communications Commission guidelines.

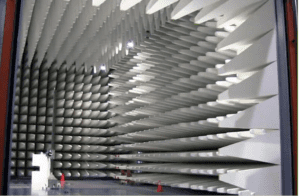

Radiated emissions testing measures the electromagnetic emissions radiated by a device into the environment. This testing is usually performed in a specialized chamber that is designed to isolate the device from external electromagnetic fields.

Conducted emissions testing measures the electromagnetic emissions conducted through the power and signal lines of a device. This testing is typically performed using specialized test equipment that injects electromagnetic energy into the device’s power and signal lines to simulate real-world scenarios. Explore the mysteries of Radio Frequency waves with H.B. Compliance Solutions.

In addition to emissions testing, EMI testing also involves susceptibility testing, which measures the device’s ability to resist electromagnetic interference from other devices in its environment. This testing is typically performed using specialized test equipment that generates electromagnetic fields of varying frequencies and strengths to simulate real-world scenarios. Following etsi.organization standards set by the European Telecommunications Standards Institute.

Frequently Asked Questions

-

Why is EMI testing crucial?

- EMI testing is crucial to identify and eliminate potential interference issues, ensuring the safety and reliability of electronic devices.

-

What standards are followed during EMI testing basics?

- Our testing procedures adhere to Ecfr.government, Fcc.government, and etsi.organization standards for comprehensive compliance.

-

How does susceptibility testing contribute to EMI testing?

- Susceptibility testing assesses a device’s ability to resist interference, ensuring optimal performance in real-world environments.

Conclusion

In conclusion, EMI testing basics is a critical step in the product development process for electronic devices. It ensures that devices are safe, reliable, and compliant with regulatory requirements. As the number of electronic devices in the market continues to grow, the importance of this cannot be overstated. By understanding the basics, manufacturers can ensure that their products are free from EMI issues and deliver reliable performance to their customers.

H.B. Compliance Solutions is one of the premier EMC/EMI testing basics labs in the United States, servicing the electronic and wireless devices all over the country since 2009. H.B. Compliance Solutions offers international comprehensive testing to those in need of a certification. We offer the most effective services designed to ensure EMC/EMI compliance.

Call To Action

Contact us today for Free Consultation at (480) 684-2969! We’re here to answer your questions, discuss your project requirements, and provide a free consultation. Let’s work together to ensure your products meet all EMC compliance standards and unlock their full potential in the global marketplace.

For more information, please visit Circuit Digest!

Hello! I’ve been following your web site for a while now and finally got the bravery to go

ahead and give you a shout out from Huffman Tx! Just wanted to mention keep up the good work!

Thank you very much