Electromagnetic Compatibility (EMC) is a critical aspect of product design and development, ensuring that electronic devices can coexist harmoniously without causing or succumbing to unwanted electromagnetic interference (EMI). Compliance with EMC regulations is not just a legal requirement in most markets, but also a vital step towards building robust, reliable, and safe products. Achieving this compliance necessitates rigorous testing using specialized EMC test equipment.

This comprehensive guide delves into the world of EMC test equipment, exploring the different types of equipment, their applications, key specifications, and considerations for selecting the right tools for your EMC testing needs. Whether you’re a seasoned EMC engineer or just starting to navigate the complexities of electromagnetic compatibility, this article aims to provide valuable insights into the essential equipment that forms the backbone of effective EMC testing.

Understanding the Fundamentals of EMC Testing

Before diving into specific equipment, it’s important to understand the two primary categories of EMC testing:

- Emissions Testing: This focuses on measuring the unintentional electromagnetic energy radiated or conducted by a device. The goal is to ensure that the device’s emissions are below the limits defined by relevant EMC standards.

- Immunity Testing: This assesses the device’s ability to function correctly in the presence of external electromagnetic disturbances. It simulates real-world scenarios where the device might be exposed to various forms of EMI.

EMC standards vary depending on the industry (e.g., automotive, medical, consumer electronics) and the geographical region (e.g., EU, North America, Asia). Common standards include CISPR, IEC, EN, and FCC. Knowing the relevant standards for your product is crucial for selecting the appropriate test methods and equipment.

Key Categories of EMC Test Equipment

The range of EMC test equipment is broad, encompassing specialized instruments for generating, measuring, and analyzing electromagnetic signals. Here’s an overview of the most common categories:

1. Spectrum Analyzers:

Function: Spectrum analyzers are fundamental tools for emissions testing. They display the amplitude of electromagnetic signals across a specific frequency range, allowing engineers to identify and measure unwanted emissions.

Applications: Primarily used for measuring radiated and conducted emissions. They can identify the frequencies at which emissions are occurring and quantify their levels.

Key Specifications:

Frequency Range: This specifies the range of frequencies that the analyzer can measure. It must cover the relevant frequency bands for the applicable EMC standards.

Resolution Bandwidth (RBW): Determines the analyzer’s ability to distinguish between closely spaced signals. A narrower RBW improves resolution but increases sweep time.

Sensitivity: The minimum signal level that the analyzer can reliably detect. Higher sensitivity is crucial for detecting weak emissions.

Amplitude Accuracy: The accuracy with which the analyzer measures the amplitude of the signal.

Dynamic Range: The difference between the maximum signal level the analyzer can handle and the minimum detectable signal.

Considerations: Choose an analyzer with a frequency range that encompasses the frequencies relevant to your product and the applicable standards. Consider features like preamplifiers, detectors (peak, quasi-peak, average), and advanced analysis capabilities (e.g., automated limit line comparison). Real-time spectrum analyzers offer significantly faster sweep times for troubleshooting.

2. EMI Receivers:

Function: EMI receivers are specialized spectrum analyzers that comply with the stringent requirements of EMC standards like CISPR and EN. They incorporate specific detectors (quasi-peak, average, RMS) and bandwidths defined by these standards.

Applications: Used for performing formal compliance testing of radiated and conducted emissions.

Key Specifications: Similar to spectrum analyzers, but with added emphasis on compliance with EMC standards. Key specifications include:

Detector Types: Must support the required detector types (quasi-peak, average, CISPR-average, RMS) specified in the applicable standards.

Bandwidths: Must support the required resolution bandwidths defined in the applicable standards.

Compliance with Standards: Certifications demonstrating compliance with relevant EMC standards (e.g., CISPR 16).

Considerations: EMI receivers are typically more expensive than general-purpose spectrum analyzers due to their specialized features and the need for compliance certifications. Consider whether you require a fully compliant receiver for formal testing or if a spectrum analyzer with appropriate detectors and bandwidths can suffice for pre-compliance testing and troubleshooting. Features like automated test sequences and report generation can significantly streamline the testing process.

3. Signal Generators:

Function: Signal generators are used to generate controlled electromagnetic signals for immunity testing. They produce various waveforms, including continuous wave (CW), modulated signals, and pulsed signals.

Applications: Used to simulate real-world electromagnetic disturbances, such as radio frequency (RF) fields, transients, and electrostatic discharges (ESD).

Key Specifications:

Frequency Range: The range of frequencies that the generator can output.

Output Power: The maximum power level that the generator can deliver.

Modulation Capabilities: The types of modulation supported (e.g., AM, FM, PM, pulse modulation).

Waveform Capabilities: The types of waveforms that can be generated (e.g., sine wave, square wave, triangle wave, arbitrary waveforms).

Accuracy and Stability: The accuracy and stability of the generated frequency and amplitude.

Considerations: Select a signal generator with sufficient output power and frequency range to meet the immunity tests you need to perform. Consider the types of modulation and waveforms required by the applicable standards. Arbitrary waveform generators offer greater flexibility for simulating complex disturbances.

4. Amplifiers:

Function: Amplifiers boost the power of signals generated by signal generators to achieve the required field strengths for immunity testing.

Applications: Used in conjunction with signal generators and antennas to create the electromagnetic fields required for radiated immunity testing.

Key Specifications:

Frequency Range: The range of frequencies that the amplifier can amplify.

Gain: The amount of amplification provided by the amplifier.

Output Power: The maximum power that the amplifier can deliver.

Linearity: The amplifier’s ability to amplify signals without distortion.

Harmonic Distortion: The level of unwanted harmonics generated by the amplifier.

Considerations: Select an amplifier that covers the frequency range of your signal generator and can provide sufficient power to generate the required field strengths. Linearity is crucial for accurate immunity testing. Consider the amplifier’s input and output impedance to ensure proper matching with other equipment. Solid-state amplifiers are generally more reliable and offer better linearity than tube amplifiers.

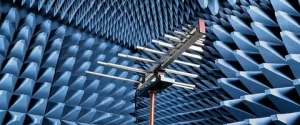

5. Antennas:

Function: Antennas are used to radiate and receive electromagnetic signals. They are essential for both radiated emissions and radiated immunity testing.

Applications: Used to radiate electromagnetic fields for immunity testing and to receive electromagnetic emissions during emissions testing.

Types:

Biconical Antennas: Used for lower frequencies (e.g., 30 MHz to 300 MHz).

Log-Periodic Antennas: Used for mid-range frequencies (e.g., 300 MHz to 1 GHz).

Horn Antennas: Used for higher frequencies (e.g., 1 GHz and above).

Loop Antennas: Used for low-frequency magnetic field measurements.

Key Specifications:

Frequency Range: The range of frequencies that the antenna can effectively radiate or receive.

Antenna Factor: A correction factor that relates the voltage measured at the antenna’s output to the electric field strength.

Gain: A measure of the antenna’s ability to focus electromagnetic energy in a particular direction.

VSWR (Voltage Standing Wave Ratio): A measure of impedance matching. Lower VSWR indicates better impedance matching.

Considerations: Choose antennas with a frequency range that covers the frequencies of interest for your testing. Antenna factors are crucial for accurate field strength measurements. Ensure proper antenna calibration to minimize measurement errors.

6. LISNs (Line Impedance Stabilization Networks):

Function: LISNs provide a standardized impedance for conducted emissions measurements. They isolate the device under test (DUT) from the power line impedance, ensuring consistent and repeatable measurements.

Applications: Used for conducting emissions testing to ensure a standardized impedance environment.

Key Specifications:

Impedance: Typically 50 ohms, as required by most EMC standards.

Frequency Range: The range of frequencies over which the LISN maintains the specified impedance.

Voltage and Current Ratings: The maximum voltage and current that the LISN can handle.

Compliance with Standards: Certification demonstrating compliance with relevant EMC standards (e.g., CISPR 16).

Considerations: Choose an LISN that complies with the relevant EMC standards for your product. Ensure the voltage and current ratings are sufficient for the DUT.

7. ESD Simulators (Electrostatic Discharge Simulators):

Function: ESD simulators generate high-voltage electrostatic discharges to simulate real-world ESD events.

Applications: Used for immunity testing to assess the DUT’s ability to withstand ESD strikes without damage or malfunction.

Key Specifications:

Voltage Range: The range of voltages that the simulator can generate.

Discharge Network: The characteristics of the discharge circuit (e.g., RC values).

Rise Time: The speed at which the voltage rises during a discharge.

Waveform Characteristics: The shape of the discharge waveform.

Compliance with Standards: Certification demonstrating compliance with relevant EMC standards (e.g., IEC 61000-4-2).

Considerations: Choose an ESD simulator that complies with the relevant EMC standards for your product. Ensure the voltage range and discharge network characteristics are appropriate for the test requirements.

8. EFT/Burst Generators (Electrical Fast Transient/Burst Generators):

Function: EFT/Burst generators generate bursts of high-voltage transients to simulate switching transients caused by inductive loads or relay contacts.

Applications: Used for immunity testing to assess the DUT’s ability to withstand EFT/burst disturbances without damage or malfunction.

Key Specifications:

Voltage Range: The range of voltages that the generator can generate.

Burst Frequency: The rate at which bursts of transients are generated.

Pulse Width: The duration of each transient pulse.

Repetition Rate: The rate at which the pulses are repeated within a burst.

Compliance with Standards: Certification demonstrating compliance with relevant EMC standards (e.g., IEC 61000-4-4).

Considerations: Choose an EFT/Burst generator that complies with the relevant EMC standards for your product. Ensure the voltage range, burst frequency, pulse width, and repetition rate are appropriate for the test requirements.

9. Surge Generators:

Function: Surge generators generate high-energy surges to simulate lightning strikes or power line disturbances.

Applications: Used for immunity testing to assess the DUT’s ability to withstand surge disturbances without damage or malfunction.

Key Specifications:

Voltage Range: The range of voltages that the generator can generate.

Current Range: The range of currents that the generator can deliver.

Waveform Characteristics: The shape of the surge waveform (e.g., 1.2/50 µs voltage waveform, 8/20 µs current waveform).

Compliance with Standards: Certification demonstrating compliance with relevant EMC standards (e.g., IEC 61000-4-5).

Considerations: Choose a surge generator that complies with the relevant EMC standards for your product. Ensure the voltage range, current range, and waveform characteristics are appropriate for the test requirements.

10. Conducted Immunity Test Systems:

Function: These systems are used to inject RF signals onto power and signal lines to test conducted immunity. They often include a signal generator, amplifier, coupling/decoupling networks (CDNs), and monitoring equipment.

Applications: Conducted immunity testing according to standards like IEC 61000-4-6.

Key Specifications: Dependent on the specific components of the system. Key considerations include the frequency range, output power, and the types of CDNs available.

Considerations: Ensure the system is capable of generating the required test levels and frequencies specified in the applicable standards. Proper calibration and verification are essential.

Selecting the Right EMC Test Equipment

Choosing the right EMC test equipment is crucial for ensuring accurate and reliable testing. Consider the following factors when making your selection:

Relevant EMC Standards: Identify the applicable EMC standards for your product and choose equipment that meets the requirements of those standards.

Testing Needs: Determine the types of testing you need to perform (emissions, immunity, or both) and select equipment accordingly.

Budget: EMC test equipment can be expensive. Establish a budget and prioritize your needs to get the most value for your investment.

Performance Specifications: Carefully review the specifications of each piece of equipment to ensure it meets your performance requirements.

Calibration and Maintenance: Consider the cost and availability of calibration and maintenance services. Regular calibration is essential for ensuring the accuracy of your measurements.

Vendor Reputation and Support: Choose reputable vendors who offer reliable equipment and excellent technical support.

Automation Capabilities: Consider equipment with automation capabilities to streamline the testing process and reduce the risk of human error.

Pre-Compliance vs. Full Compliance: Determine if you need equipment for pre-compliance testing and troubleshooting or for formal compliance testing. Pre-compliance equipment may be less expensive but may not meet all the requirements of formal compliance standards.

Conclusion:

EMC testing is a critical step in ensuring the compliance, reliability, and safety of electronic products. By understanding the different types of EMC test equipment, their applications, and key specifications, you can make informed decisions about selecting the right tools for your testing needs. Remember to prioritize compliance with relevant EMC standards, budget considerations, performance specifications, and vendor reputation when making your choices. With the right equipment and expertise, you can navigate the electromagnetic minefield and ensure that your products meet the stringent requirements of the modern electronic environment.