Electromagnetic Compatibility (EMC) testing ensures that electrical and electronic devices function properly in their electromagnetic environment without causing or being affected by electromagnetic interference (EMI). The major objective of EMC testing services is to verify that a product doesn’t emit excessive electromagnetic noise and can withstand EMI from other devices. Nearly all electrical products in the modern, highly connected world must adhere to EMC guidelines before being released onto the market. From smartphones to industrial equipment, EMC test services are an essential part of the product development cycle.

What Makes EMC Testing Crucial?

EMC testing is essential for regulatory compliance, product dependability, and customer satisfaction. Devices that fail EMC tests may interfere with other electronic systems, causing malfunctions, recalls, or even legal issues. EMC-failing devices can significantly damage a brand’s credibility. On the other hand, passing EMC testing acts as a mark of quality, boosting customer trust. Partnering with reliable EMC testing services or EMC test consultation services ensures your products function properly in real-world scenarios filled with EMI sources.

Important EMC Standards to Understand

Globally, there are numerous EMC standards targeting various markets and product categories. The United States follows FCC regulations (like Part 15), while the European Union uses EN standards (e.g., EN 55032 for multimedia equipment). Other key standards include ISO, MIL-STD, CISPR, and IEC. Determining the right standard is crucial and depends on your target market and product type. Opting for the best FCC certification services can help simplify compliance with these standards. Understanding them early in the design phase avoids costly changes later.

EMC Testing Types

EMC testing is generally categorized into emissions and immunity testing. Emissions testing measures the electromagnetic noise a device produces, ensuring it stays within acceptable limits. Immunity testing evaluates the device’s resilience to external EMI without compromising performance. Common types include electrostatic discharge (ESD), radiated and conducted emissions, surge immunity, and radiated immunity. Professional EMC test services simulate real-world scenarios to verify a product’s durability and compliance.

An Explanation of the EMC Testing Process

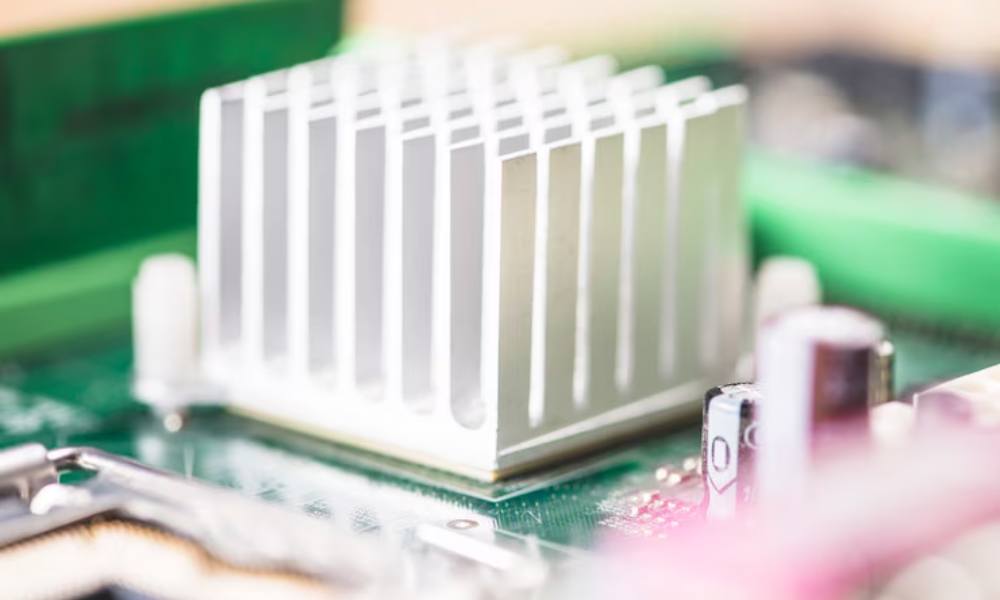

The EMC testing process begins with pre-compliance tests to detect and resolve early-stage design issues. Next comes formal compliance testing at certified labs offering EMC testing services. These labs use advanced setups including antennas, test chambers, and receivers. Engineers monitor emissions and device performance closely. If tests fail, mitigation techniques such as shielding, filtering, or PCB redesign are applied. Once the product passes, a compliance report is issued. Partnering with experienced EMC test consultation services can smooth this process.

How to Get Ready for EMC Examinations

Preparation is crucial for EMC testing success. Start by integrating EMC-friendly design principles such as proper grounding, PCB layout, and filtering. Conduct in-house pre-compliance tests and use EMC simulation software to predict issues. Ensure your documentation is complete, covering operation modes, schematics, and product descriptions. Utilizing expert EMC test consultation services can significantly increase your first-pass success rate and reduce costly delays.

Compliance and Certification for EMC

After passing EMC tests, your product becomes eligible for certification. In the EU, CE marking is mandatory, encompassing EMC directives. In the United States, products require FCC certification, such as the FCC Declaration of Conformity or full FCC Certification, depending on their classification. Companies can rely on professional FCC certification services to guide them through submission and approval processes. Conducting an FCC certification search and understanding relevant fcc certifications ensures your product can legally and competitively enter target markets.

Typical Obstacles and How to Get Past Them

Businesses often encounter challenges like failing emissions limits or unexpected immunity issues during EMC testing. These are usually caused by design flaws such as inadequate shielding or faulty PCB layout. Overcoming these obstacles requires investment in engineering training, iterative testing, and expert guidance. Use diagnostic tools like spectrum analyzers and near-field probes for pinpointing problems. Collaborating with leading EMC test services and the best FCC certification services helps ensure quicker resolutions and smoother compliance.

Conclusion

EMC testing is a crucial phase in the development of any electronic product. Understanding the standards, test types, and certification paths like those for FCC certification can streamline your journey to market. By applying EMC best practices from the start and leveraging professional EMC testing services and EMC test consultation services, manufacturers can boost reliability, customer trust, and global compliance. Whether your aim is local approval or international expansion, EMC compliance supported by trusted fcc certification services is non-negotiable in today’s interconnected world.