As an electronics manufacturer, understanding the impact that electromagnetic interference (EMI) can have on your device is crucial for avoiding performance issues and ensuring your device complies with regulations such as FCC Part 15.

EMI can disrupt the normal operation of electronic devices, leading to a decrease in product reliability and user satisfaction. It can also stop you from gaining market access in countries such as the United States, Canada and common markets such as the European Union.

A key part of analyzing and controlling electromagnetic interference is carrying out lab testing for your device. This involves the use of EMI measurement equipment to assess your device’s performance and ensure it operates in compliance with certain standards.

Below, we’ve explained what electromagnetic interference is, as well as the equipment that’s used to measure it.

We’ve also gone into more detail about common EMI measurement devices used in a testing lab setting, including spectrum analyzers and other devices.

Need help with EMI testing and compliance?To request a free quote for testing and certifying your device, or to ask our engineers a question about the certification process, contact us online or call us at info@hbcompliance.com, (480) 684-2969.

What is Electromagnetic Interference?

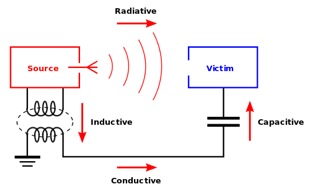

The term electromagnetic interference refers to a type of disturbance that affects an electronic circuit, either due to electromagnetic induction or electromagnetic radiation that’s emitted from an external source.

Put more simply, EMI is a disturbance that can occur when electromagnetic radiation released from one device (or, in some cases, naturally) affects the performance of another.

EMI can come from man-made sources such as broadcasting equipment, industrial equipment and other electronic devices, or from natural sources like lightning. Many consumer electronics, such as phones, appliances and other devices, can also potentially cause EMI.

Electromagnetic interference can cause a range of issues in electronic equipment, ranging from minor annoyances like static or a weak TV signal to potentially serious issues such as failures in critical industrial equipment and safety systems.

Because EMI is such a potential risk for electronic devices, the United States and other markets have established regulations to prevent electronic devices that cause interference from entering onto the market.

In the United States, these include FCC Part 15 and FCC Part 18. In the European Union, laws such as the Electromagnetic Compatibility Directive and Radio Equipment Directive (RED) stop devices that exceed emissions limits from going on sale.

How EMI is Measured

EMI is measured in an electromagnetic compliance laboratory. The process of measuring EMI involves detecting emissions as they’re produced from a device, then quantifying the levels of emissions from the device to verify if they’re within acceptable limits.

Two primary methods are used for EMI measurements. The first, radiated emissions testing, is used to measure electromagnetic fields that propagate away from an electronic device. These wireless emissions can disrupt nearby devices and cause performance issues.

The second, conducted emissions testing, involves measuring electromagnetic emissions that travel through power or signal lines. These emissions can also affect other devices that use a shared power source, potentially causing performance and/or safety issues.

Both types of testing require precise equipment to capture and analyze interference across a range of frequencies.

Common EMI Measurement Equipment

So, what equipment is used for EMI testing? Electromagnetic compatibility labs make use of several devices to measure electromagnetic interference accurately, including the following:

Spectrum Analyzers

Spectrum analyzers are tools that are used to measure electromagnetic interference. These devices identify noise, false signals, complex waveforms, and rare short-duration events that can cause performance issues in electronic devices.

A spectrum analyzer works by breaking down signals into constituent frequencies. This gives the engineer the ability to pinpoint the specific sources of EMI within a device. Conducted and radiated emissions testing both involve the use of spectrum analyzer equipment.

EMI Receivers

EMI receivers are similar to spectrum analyzers, but are designed specifically to measure the electromagnetic emissions of a device and verify that they conform with the standard to which the device is being compared.

These devices offer more precise measurements and are equipped with specific features such as peak detection, quasi-peak detection and average detection to verify that devices fully meet specific regulatory requirements.

Antennas

Antennas are used in radiated emissions testing. Antennas capture electromagnetic fields that are emitted by the device under testing, allowing for accurate measurements. Several different antenna types are used in testing, including biconical, log-periodic and horn antennas.

Measuring radiated emissions effectively depends on the correct choice of antenna and testing methods.

LISN (Line Impedance Stabilization Network)

Line impedance stabilization networks, or LISNs, are measurement devices used to monitor RF signals over a certain frequency range. These devices are used in conducted emissions testing to isolate the device under testing from external electromagnetic interference.

LISNs provide a consistent impedance to the device, making it easier to accurately measure its conducted emissions. This allows for repeatable, reliable testing with consistent measurements over time.

Pre-Amplifiers

Pre-amplifiers are used in conjunction with antennas and EMI receivers to boost weak signals, allowing for low-level emissions to be measured accurately. They’re typically used for radiated emissions testing, where capturing the full spectrum of emissions from a device often requires sensitivity to weak signals.

TEM (Transverse Electromagnetic) Cells

Transverse electromagnetic cells, or TEM cells, provide a controlled environment for analyzing and measuring radiated emissions, particularly at lower frequencies. They allow for precise and effective measurement of electromagnetic fields in a confined space.

TEM cells also reduce the impact of external EMI and reflection effects, which can skew results in some testing environments.

Absorbing Clamps

Absorbing clamps are used in conducted emissions testing to measure interference on cables that are connected to the device under test. These work by absorbing electromagnetic energy on the cable and converting it into a measurable voltage.

This provides a direct way to quantify conducted emissions that travel along cables, which are one of the more common sources of electromagnetic interference.

Contact Us for EMI/EMC Testing Services

Completing EMI/EMC testing for your device is one of the most important steps towards getting FCC equipment authorization, earning the FCC mark, and allowing your electronic device to go on sale in the United States.

As an ANSI-accredited electronics testing lab, we’ve helped hundreds of manufacturers carry out EMI/EMC testing and achieve FCC equipment authorization. We’ve also assisted product manufacturers with CE compliance, Canada ISED compliance, and other compliance marks.

To ask our engineers and compliance specialists a question about the testing and certification process, or to request a free, no-obligation quote for testing your device, contact us online or call us at info@hbcompliance.com, (480) 684-2969.